Many industries such as textiles, packaging, and manufacturing depends on paper cores and plastic cones. These products are used to wrap yarns, threads, films, foils, papers, and more. Even though their purpose is the same, they are not. As they both have their unique properties, benefits, and uses.

Have you ever wondered what sets paper cores apart from plastic cones? If yes, then you have come to the right place. In this article we will give a clear and easy-to-understand explanation for both. This guide will provide a detailed explanation.

What are Paper Cores?

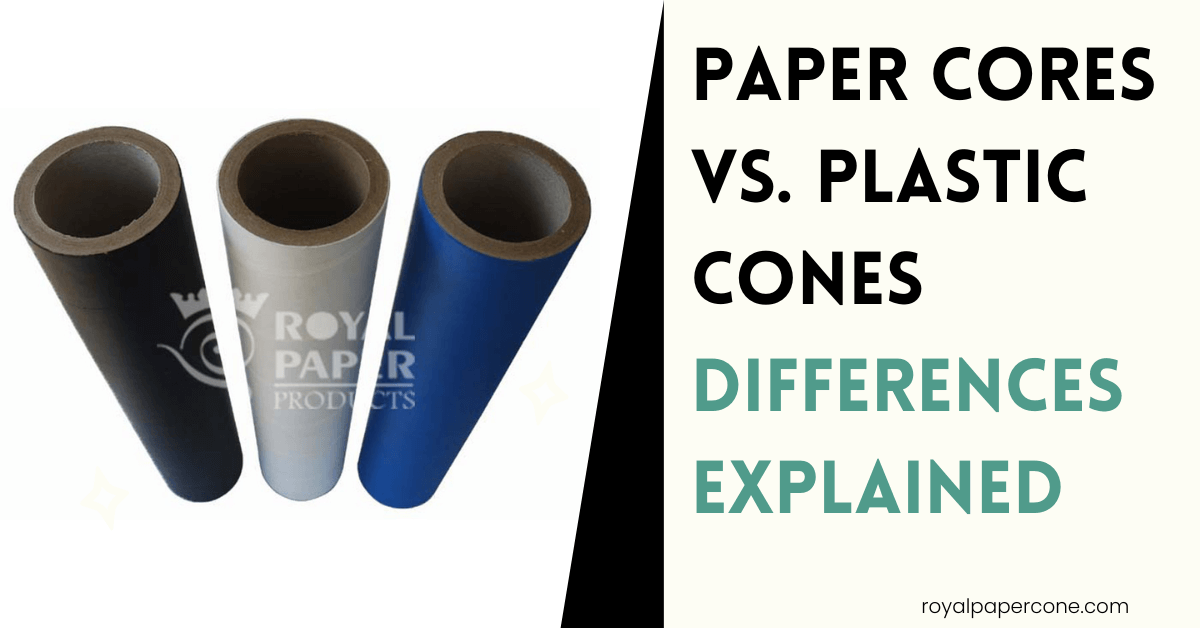

Paper cores are cylindrical products. They are made from kraft paper layers or board that are wrapped tightly and sticked together properly. These cores are used in industries like packaging, textiles, paper mills, and film production.

If you are buying tissue paper rolls or adhesive tape, for instance, it is a paper core. Paper cores are available in different sizes and designs, and are long-lasting, eco-friendly materials.

A paper core manufacturer can customize these products according to client’s requirements.

What are Plastic Cones?

On the other hand, plastic cones are tapered winding tools made from strong plastic materials. These are used in the textile industry for wrapping yarns and threads. Unlike paper cores, plastic cones have conical shapes.

Plastic cones are designed to handle high-speed winding machines and can handle more ear and tear. As these cones are made up of plastic, they are long-lasting and reusable.

Key Differences Between Paper Cores and Plastic Cones

Let me help you with the main differences between paper cores and plastic cones –

1) Material

- Paper Cores – It is made from layers of kraft paper or cardboard.

- Plastic Cones – It is made from durable plastics like polypropylene or high-density polyethylene.

2) Shape

- Paper Cores – It is cylindrical in shape like a tube.

- Plastic Cones – They are conical in shape.

3) Durability

- Paper Cores – It is strong but not durable as plastic. It is for single use.

- Plastic Cones – It is durable, resists damages and is reusable.

4) Eco-Friendliness

- Paper Cores – They are an eco-friendly option. As they are biodegradable and recyclable.

- Plastic Cones – It is not biodegradable and can be reused many times.

5) Cost

- Paper Cores – It is affordable as it is made from paper material.

- Plastic Cones – Initially it has a high cost, but later you have to spend money again and again.

6) Applications

- Paper Cores – It is widely used in packaging, adhesive tapes, films, paper rolls, and lightweight textile applications.

- Plastic Cones – It is primarily used in textiles for yarn and thread winding.

Advantages of Paper Cores

Paper cores are eco-friendly and cost-effective. Some key advantages include –

- Environmentally Friendly – It is recyclable and biodegradable.

- Customizable – It can be manufactured in different lengths, diameters, and thicknesses.

- Cost-Effective – The prices are affordable.

- Lightweight – As it is lightweight, it is very easy to handle and you can transport anywhere.

This makes paper cores a go-to choice for industries. Industries who focus on eco-friendly items and budget-friendly solutions.

Advantages of Plastic Cones

Plastic cones benefits include –

- High Durability – As it is made from plastic, it can be used multiple times.

- Reusable – You don’t have to buy again and again as it is reusable.

- Consistency – It provides uniform shape and quality for textile operations.

- Resistance to Moisture and Chemicals – It is ideal for harsh production environments.

These are the reasons textile manufacturers rely on plastic cones.

Choosing the Right Option for Your Industry

The choice between paper cores and plastic cones totally depends on what your business needs.

- Paper cores are ideal for packaging, adhesive tapes, or paper production. As it is affordable and eco-friendly.

- Plastic cones are suitable for strength and reusability. It is perfect if you are in the textile industry.

Many businesses work with paper cores manufacturers who can guide them for the best products according to their requirements. A reliable manufacturer can provide high-quality products so choose wisely.

Why Working with the Right Manufacturer Matters?

Choosing the right manufacturer is important, whether your business needs paper cores or plastic cones. A good manufacturer will –

- Offer high-quality and durable products

- Customize dimensions and specifications according to your needs

- Make sure on-time delivery for uninterrupted production

- Provide eco-friendly and cost-effective solutions.

With the help of a reliable supplier, businesses can save money, reduce waste, and improve their operations.

Final Thoughts

You may think that paper cores and plastics are simple tools. But they play a very important role in industries. Paper cores are cost-effective, eco-friendly, and versatile, while plastic cones are durable, reusable, and ideal for heavy-duty applications

Deciding between the two totally depends on your industry, usage requirements, and budget. By working with paper cones manufacturers, you can make sure that you get the right products.

Now you will know what that little core or cone is hiding behind that next time you see tape, yarn, or film!