Plastic cones are probably not the first thing that comes to mind when we think of packaging solutions in manufacturing industries. But for wire, cable, and yarn manufacturers, these plastic cones are important for smooth operations. Over the years now, the cone has gone through huge transformations.

Today, top plastic cone manufacturers and plastic cone exporters are reconsidering the way to store, transport, and unwind wire, cable, and yarn. So, let us talk about innovations in packaging products.

Understanding the Importance of Plastic Cones

Before exploring the innovations, it is important to understand why plastic cones matter.

For industries who handle materials like wire, electric cables, textile yarns, ropes, tapes, and threads; plastic cones hemp to maintain the material in perfect working condition.

They make sure –

- Smooth unwinding

- Precise winding

- Protection from damage

- Organized storage

- Easy transportation

Plastic cones have become an irreplaceable packaging thing because of the following benefits.

1) Advanced Polymer Materials for Superior Strength

One of the biggest innovations is the use of high-performance polymers. The cones of the past were made of basic plastics, which worked fine but tended to crack under pressure, deform in heat, or wear out quickly.

Today, plastic cone manufacturers use materials like –

- Polypropylene (PP)

- High-Density Polyethylene (HDPE)

- Nylon Blends

- Glass-Filled Polymers

These materials offer higher impact resistance, better load-bearing capacity, and improved thermal stability. To be frank, for industries who handle heavy cables or high-tension wire, these innovations are to make operations smooth and safe.

Benefits for users – Long-lasting cones reduce downtime, replacement costs, and the risk of product damage.

2) Precision-Molded Cones for Tangle-Free Winding

Traditional cones were not in perfect shape, which leads to wobbling, uneven winding, or tangles during unwinding. This is a major issue in yarn spinning mills and cable manufacturing lines.

Modern plastic cones are produced using precision injection molding technology, making sure –

- Uniform dimensions

- Perfect taper angles

- Smooth surfaces

- Accurate weight distribution

This helps in maintaining proper tension during winding and also prevents snags or jerky movements during unwinding.

And the result is greater productivity and consistent product quality.

3) Customized Designs for Different Industry Needs

In the case of wire, yarn, and cable packaging, one size does not fit all. That is why plastic cone exporters and manufacturers offer extensive customization options. These includes –

a) Different Shapes

- Conical

- Cylindrical

- Hybrid shapes

- Step-tapered cones

b) Color Coding

- Mini cones for fine yarns

- Heavy-duty cones for industrial cables

- Medium-sized cones for ropes and technical textiles

c) Branding & Labeling

Manufacturers do provide color-coded cones to help industries that quickly identify materials or production batches. This simple innovation will reduce mix-ups and speed up workflow.

d) Branding & Labeling

Some companies embed logos, QR codes, or barcodes directly into the cones for easy inventory tracking.

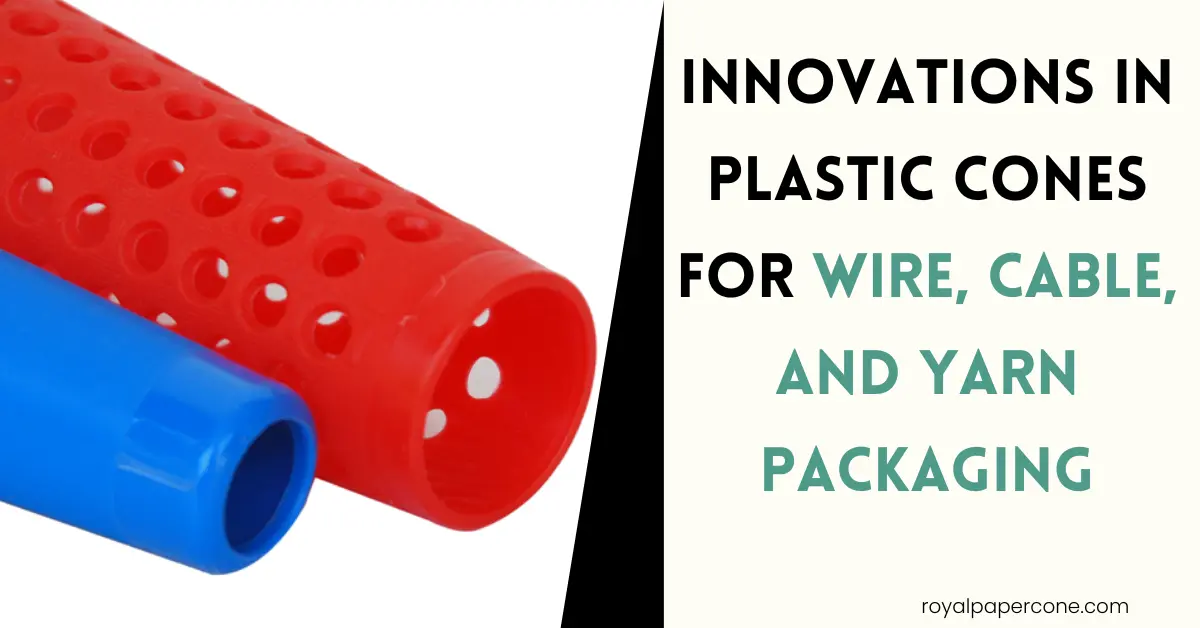

4) Innovations in Ventilation and Surface Design

In yarn and thread manufacturing, airflow is important to maintaining material quality.

New generation plastic cones come with –

- Engineered ventilation grids

- Micro-perforations

- Smooth or textured surfaces

These improvements will help maintain yarn freshness, reduce moisture buildup, and improve winding efficiency. The texture of the surface provides a better grip during high-speed winding of wire and cable packaging, reducing slippage.

5) Lightweight Yet High-Strength Cones

As industries are targeting to reduce transport costs and improve handling, lightweight plastic cones are a popular innovation.

Thanks to –

- Reinforced ribs

- Advanced polymer blends

- Hollow-core designs

Manufacturers are producing cones that weigh less but offer superior load strength. This is beneficial for international shipments handled by plastic cone exporters.

6) Eco-Friendly and Recyclable Plastic Cones

Industry is actively seeking eco-friendly solutions across the globe. Sustainability is no longer optional.

Modern plastic cone manufacturers introduced –

- Recyclable PP and HDPE cones

- Reprocessed plastic cones that is made from recycled materials

- Low-carbon footprint manufacturing techniques

Some companies offer buy-back programs where used cones are collected, recycled, and remolded into new ones. This will reduce waste and will support circular manufacturing practices.

7) Heat-Resistant and Chemical-Resistant Cones

A wide range of industries, including the production of electrical wires and chemical fibers, often handle harsh substances and high temperatures.

Manufacturers make cones with –

- Heat stabilization additives

- Anti-corrosion properties

- UV-resistant coatings

These innovations help cones against aggressive environments without deforming or degrading. Industries do benefit from improved durability and safety and especially during long production cycles.

8) Smart Cones with Tracking & Monitoring Features

One of the most modern innovations is smart technology into plastic cones. Some advanced manufacturers offer –

- Embedded RFID tags

- QR-coded cones

- GPS-enabled tracking for large cable reels

These features will allow factories to monitor inventory, track cones across supply chains, and analyze usage patterns. Manufacturing is taking a step toward digitalization and automation.

9) Automation-Friendly Cone Designs

As factories are adopting robotic handling and automated winding systems, plastic cones are for you.

Automation-friendly innovations include –

- Precise grip points for robotic arms

- Smooth edges for machine compatibility

- Reinforced bases to prevent slippage

- Uniform shapes detectable by sensors

This makes sure seamless integration with modern machinery and reduces downtime caused by incompatible packaging components.

10) Cost-Effective Production Techniques

Manufacturers redefine the production process constantly to reduce costs while improving quality.

New innovations include –

- Multi-cavity injection molds

- Automated finishing systems

- Energy-efficient machinery

- Waste recycling within the manufacturing unit

These improvements will help plastic cone exporters offer competitive prices without compromising on product performance.

Looking Ahead: The Future of Plastic Cones

As wire, cable, and yarn packaging needs evolve, plastic cone technology will also grow. Our cones will become even smarter, stronger, and more customizable as sustainability, automation, and precision become top priorities. The more up-to-date you are about these innovations, the smoother your operations will be, the better quality your product will be, and the more efficient you will be.

Final Thoughts

Plastic cones may seem like simple accessories, but they play an essential role in packaging and production. Thanks to continuous research and technological advancement, modern cones offer unmatched durability, precision, and performance.

For high-quality, innovative solutions, working with reliable Plastic Cone Manufacturers and Plastic Cone Exporters is key. Their expertise and advanced production techniques ensure you get packaging components that meet the specific demands of your industry.